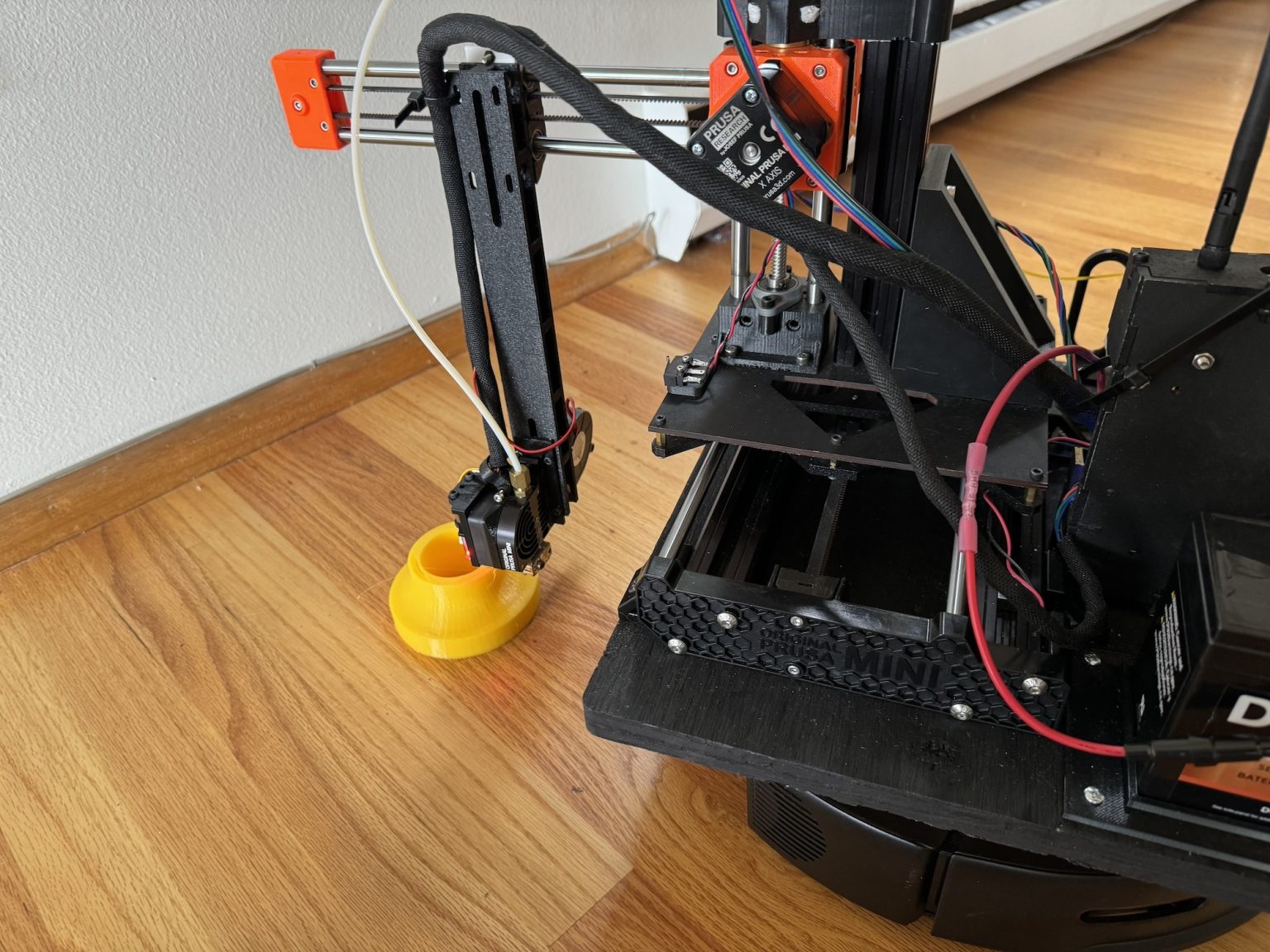

The University of Washington has created a mobile 3D printer called MobiPrint that can measure a room and print objects directly onto the floor. The printer is built onto a modified vacuum robot and has the ability to roam autonomously within an indoor space using LiDAR to map it. The device provides users with the opportunity to print a variety of objects from artistic pieces to practical items like tactile markers for blind individuals or ramps to cover uneven flooring transitions.

MobiPrint works by allowing users to upload a design or select an object from the printer’s library. The user can then pick a location on the map of the room to print the object and use the design interface to scale and position it accordingly. Once the location is selected, the robot moves to that spot and begins printing the object directly onto the floor using common 3D printing bioplastics. This innovative approach to 3D printing aims to expand its application beyond traditional table-top printers and make it more accessible to a wider range of users.

The goal of MobiPrint is to change the built environment and customize spaces to meet people’s specific needs, whether it be for accessibility reasons or aesthetic preferences. Daniel Campos Zamora, a doctoral student in the Paul G. Allen School of Computer Science & Engineering at the University of Washington, emphasized the importance of using 3D printing technology to tailor spaces for individuals based on their needs and tastes. By lowering the barriers for people to use 3D printing, MobiPrint has the potential to revolutionize the way objects are created and integrated into various environments.

In addition to providing users with the ability to print objects directly onto the floor, MobiPrint also offers a design tool that converts the room map into an interactive canvas. This allows users to interact with the space and visualize how different objects would look in the room before printing them. The printer’s ability to measure and map a room autonomously streamlines the printing process and gives users more control over the objects they create. By presenting their work at the ACM Symposium on User Interface Software and Technology, the UW team has demonstrated the potential of MobiPrint to transform the way people interact with their living spaces through customized 3D printed objects.

The research behind MobiPrint was funded by the National Science Foundation and was co-authored by Liang He, an assistant professor at Purdue University who was a doctoral student in the Allen School during the research. This collaboration between researchers from different institutions reflects the interdisciplinary nature of the project and highlights the potential impact of MobiPrint on the field of 3D printing technology. With its innovative approach to creating customized objects in indoor spaces, MobiPrint has the potential to revolutionize the way people interact with their environments and make 3D printing technology more accessible and versatile.