Summarize this content to 2000 words in 6 paragraphs

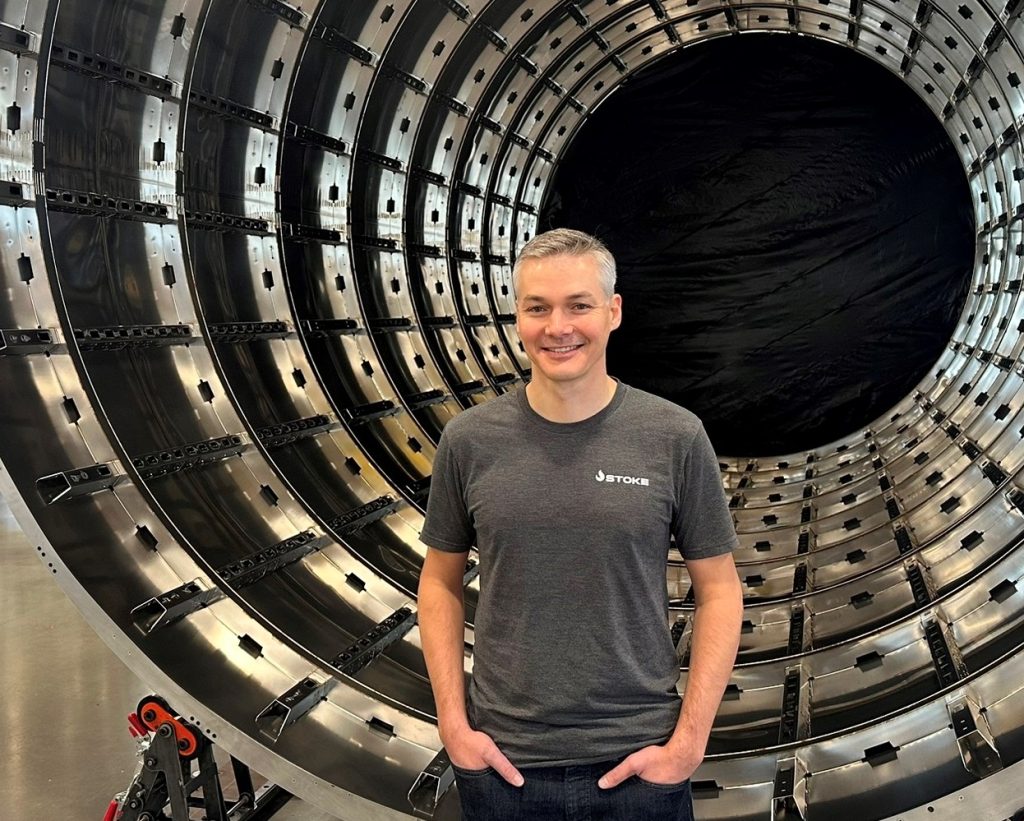

Stoke Space CEO Andy Lapsa is framed by a propellant tank that’s taking shape at the startup’s rocket factory in Kent, Wash. (GeekWire Photo / Alan Boyle)

Editor’s note: This is part of a series profiling five of the Seattle region’s “Uncommon Thinkers”: inventors, scientists, technologists and entrepreneurs transforming industries and driving positive change in the world. They will be recognized at the GeekWire Gala on Dec. 12. Uncommon Thinkers is presented in partnership with Greater Seattle Partners. Read the profiles here.

KENT, Wash. — Like two of the world’s best-known billionaires, Elon Musk and Jeff Bezos, Stoke Space CEO Andy Lapsa is passionate about making spaceships as reusable as airplanes.

“Part of the big thesis of the company is, how do you build a fully, rapidly reusable space vehicle that goes to space, performs a function, comes back and turns around and flies again,” he says. “That’s not a new vision. We’ve been dreaming about fully reusable spacecraft since the ’50s and ’60s, and probably before that. So the big question is, how do you do it?”

Unlike Bezos or Musk, Lapsa isn’t a billionaire. Instead, he made his case to backers who have billions of dollars to invest. Those backers include Microsoft co-founder Bill Gates, whose investments in Stoke have been made through Breakthrough Energy Ventures, a fund that focuses on clean-tech innovations for the climate challenge.

Rockets that fight climate change? That’s part of Lapsa’s uncommon perspective on the benefits of reusable rocket ships.

From grasshoppers to rocket hoppers

Stoke Space’s Hopper2 rocket vehicle fires its engine during a test “hop” in 2023. (Stoke Space Photo)

Lapsa’s interest in space dates back to his childhood in the 1980s and ’90s. While NASA was flying space shuttles, Lapsa was a kid flying model rockets in Pennsylvania.

“I built a lot of Estes rockets, and would launch them in ways that sometimes my parents weren’t thrilled with,” the 42-year-old Lapsa recalls. “They had these little payload compartments, and my sister wasn’t pleased with my payload selections. … I had a lot of fun with that. Grasshoppers got to experience flight.”

His childhood aspiration was to become an architect, but he ended up gravitating toward engineering. After getting his bachelor’s degree in mechanical engineering at Cornell, he went on to earn a Ph.D. in aerospace, aeronautical and astronautical engineering at the University of Michigan. It was at U-M that he found his passion: fluids, combustion and propulsion. In short, lighting things up and making things go.

Lapsa followed his passion to the Seattle area, and went to work for Bezos’ Blue Origin space venture in Kent. He played a lead role in developing the company’s propulsion systems, including the BE-3, BE-3U and BE-4 rocket engines. That’s how he connected with Stoke’s other co-founder, chief technology officer Tom Feldman.

Soon, the seeds of a startup took root.

“Look, I have 1,000% conviction that the world will move to fully reusable vehicles,” Lapsa says. “I thought it had to be worked on with a very concerted effort. And so I looked around the industry to figure out who was working on it.”

Full reusability is much more than just a technical accomplishment: For decades, launch companies basically threw away their multimillion-dollar machines after a single use. The stunning success of Elon Musk and SpaceX sprang from that company’s ability to use most of its rocket hardware over and over again, dramatically lowering the cost of access to space.

Less expensive launches can open up new prospects on the final frontier — ranging from the satellite mega-constellation that SpaceX has put into orbit for its Starlink broadband network, to Breakthrough Energy Ventures’ interest in monitoring Earth and its climate in greater detail at lower cost.

Bezos has called full reusability the “Holy Grail of rocketry,” and Lapsa agrees.

So what’s the next frontier? Lapsa recalls that he saw “a lot of noise in the industry,” but not a lot of strong signals about fresh approaches to rocket reusability. “At that point, I started talking to Tom, not in the spirit of making a new company,” Lapsa says. “But as we started talking about it, it became clearer and clearer that that next company is not out there yet. We’ve got to start it.”

Leaving Blue Origin wasn’t easy. “It’s pretty uncommon to see startup founders who have families,” Lapsa says. “And the decision to leave a well-paying, stable job with a family to feed and go off on your own, give away your salary, and walk into this world of wild uncertainty … That was a heavy decision for sure.”

In contrast, Feldman recalls feeling a sense of relief when he and Lapsa founded Stoke Space in 2019. “I knew for a long time that I wanted to go start a company, and I didn’t know what it was going to be. I don’t think I ever dreamt that it would be this. But the more we looked at it, the clearer it became,” Feldman says.

“It’s the inevitable future,” he explains. “Five, 10, 50 years from now, somebody’s going to figure out how to not throw these things away in the ocean. We didn’t see anybody working in earnest on it, and we felt like we knew a pretty good solution to how you might solve that problem.”

Stoke Space won research grants from the National Science Foundation and NASA, and raised $9.1 million in seed funding in 2021. The company quickly set up a development and testing site in Moses Lake in central Washington state.

Then the startup really took off: Stoke raised $65 million in a funding round led by Breakthrough Energy Ventures. It secured the right to use Cape Canaveral’s Launch Complex 14 — the place from which John Glenn lifted off for his historic orbital flight in 1962. And it built two prototype “Hopper” rockets to test the technologies required for a fully reusable second stage.

Stoke Space’s ascent entered a whole new stage in September 2023, when its Hopper2 prototype blasted off at the Moses Lake testing site, rose 30 feet in the air, and settled back to the ground after firing its ring of 15 thrusters for 15 seconds.

After that test, Lapsa said his team learned all they needed to learn from the Hoppers. “The focus is now very centrally on getting to orbit,” he said.

Inside the rocket factory

Tom Feldman, Stoke Space’s co-founder and chief technology officer, stands beside Hopper2, a development rocket vehicle that made a short-hop flight in 2023. (GeekWire Photo / Alan Boyle)

Today, Hopper2 occupies a place of honor on the factory floor in Stoke Space’s 168,000-square-foot headquarters facility. The factory was built from the ground up in Kent, not far from the founders’ old stomping grounds at Blue Origin.

All that square footage means there’s room to spread out. There’s a row of sheet-metal cylinders that will be turned into propellant tanks, a full-featured machine shop, and a phalanx of giant 3-D printers that can turn out components for Stoke’s rocket engines. One of the first-stage engines that recently went through hot-fire testing in Moses Lake was being fine-tuned in Kent for the next round of tests.

“We’re going after the highest-performance rocket engine architecture you could possibly have, called full-flow staged combustion,” Lapsa said. “It’s only been tried three times in the history of the world before — one time successfully, by SpaceX and the Raptor. And so, for us, as a small little startup, to start going after this and trying to do it at the scale that we’re doing — it was an aggressive technical decision, but we got that engine started up earlier this year.”

The plan for Nova’s first stage is innovative, but the plan for the second stage is even more so. So far, only SpaceX has managed to bring the second stage of a two-stage rocket back down from space in one piece, during tests of its Starship super-rocket. Typically, the second stage of the rocket is left to burn up in the atmosphere after it’s done its job. It’s just too hard to recover it.

Stoke Space’s co-founder and chief technology officer, Tom Feldman, points out the thrusters that were installed on Hopper2’s propulsion ring for second-stage rocket testing. (GeekWire Photo / Alan Boyle)

Lapsa and the rest of the Stoke team are aiming to fix that. Like Hopper2, Nova’s second stage will have a ring of small hydrogen-fueled thrusters for propulsion and attitude control. But it will also have a metallic heat shield that’ll be cooled by liquid hydrogen fed out through tiny channels in the metal.

It’s an approach that’s different from the one used by SpaceX for Starship, which relies on ceramic tiles for thermal protection. Last week, in a posting to the X social-media platform, Lapsa took note of Musk’s observation that “the biggest technology challenge remaining for Starship is a fully and immediately reusable heat shield.”

“This was sort of our founding thesis,” Lapsa wrote in response. “Stoke Space’s heat shield is literally bulletproof.”

Lapsa says the idea of having a liquid-cooled heat shield was “stuck in our brains” from early on. “It’s a really, really robust way to keep things cool, and that’s the thing that we couldn’t get out of our head,” he says. “And the question then was, all right, how do you build a vehicle around that and make it mass-efficient enough to still perform the space function that it has to serve?”

That’s the task facing Lapsa, Feldman and their team of 160 employees. Like Blue Origin, Stoke follows a ferocious step-by-step development timeline, starting with engine testing. And like SpaceX, Stoke embraces the strategy of trying, perhaps failing, learning, and then quickly trying again.

“We thoroughly buy into the idea of rapid iteration,” Lapsa says. “It comes down to a lot of engineering judgment about where the line is. We talk a lot internally about ‘scrappy vs. crappy.’ It can’t be crappy. … If you’re going to fail, we should learn a good lesson out of it.”

One of the secrets of success has to do with the way the roles of the founders mesh. “Andy has done a super awesome job at running the business, raising the capital,” Feldman says. “My role is a lot more technically focused. … My main job is to go gather information and help us make smart choices.”

The road ahead

Stoke Space technician Xue Vue works on a development version of a first-stage engine that’s been tested at Stoke’s Moses Lake facility. (GeekWire Photo / Alan Boyle)

If everything goes just right, Stoke Space could launch its first Nova rocket from Florida by the end of next year. But that launch won’t be a short-range hop like the one that was done in Moses Lake.

“The next hop will go to orbit,” Lapsa says.

Then what? A year from now, SpaceX’s fully reusable Starship could be flying more than 100 tons of cargo to low Earth orbit on each flight, and Blue Origin’s New Glenn rocket could be carrying up to 45 tons to orbit. Will there be room for Stoke Space?

Finding a niche alongside SpaceX may sound scary, but Lapsa is undaunted.

“The question that we get more frequently is, ‘What do you do when Starship comes online?’ And I’m personally super excited for that world,” Lapsa says. “I think that helps us lay heavy infrastructure in space. I think it creates more opportunity for the rest of the industry, including us.”

Lapsa argues that there’ll be room for launch companies that can offer fully reusable rockets with medium-lift capability — that is, the ability to send between two tons and 20 tons of payload to low Earth orbit.

“You need to be able to compete on the cost basis, and you need to be able to compete or win on other things like availability, like offering direct flights rather than rideshares,” he says. “And so, Starship will put pressure on the industry to follow suit with full reusability, because it just fundamentally changes the cost.”

Stoke Space’s first-stage rocket engine is installed on a vertical test stand at the company’s Moses Lake testing site. “Super important to get this learning early in the dev program,” Tom Feldman, Stoke’s co-founder and chief technology officer, said in a posting to the X social-media platform. (Stoke Space Photo via X)

Stoke’s investors have bought into Lapsa’s argument. After last year’s hop, the company received its biggest infusion of capital to date — $100 million — and once again, Breakthrough Energy Ventures was in on the funding round.

Why should a venture fund focused on clean tech invest in an industry that typically generates lots of smoke and fire? Lapsa has an answer: Spaceborne sensors are playing an increasingly important role in tracking the effects of climate change. Cheaper access to space could result in better data for climate scientists.

“Having a vantage in space for persistent and more global perspectives is really important, and there are just a whole lot of sensors and detection methods that can go up there,” Lapsa says.

That selling point resonates with Breakthrough Energy Ventures.

“Stoke is at the forefront of demonstrating how space technologies can play a role in decarbonization,” Christian Garcia, a partner at Breakthrough Energy Ventures, said in an emailed statement. “The company has already made significant strides in its advanced and reusable space launch vehicles that unlock a variety of climate opportunities, from detecting methane leaks and wildfires in real time to protecting natural resources like our forests and oceans.”

Lapsa also earned an extra dollop of praise from Garcia.

“With Andy at the helm, Stoke is uniquely positioned to make the space economy both sustainable and scalable, while solving climate problems on Earth,” Garcia said.

Why stop at planet Earth? For now, Lapsa and his team are totally focused on getting Nova flying. But when you ask him whether Stoke Space’s aspirations are limited to low Earth orbit, Lapsa declines to be locked in.

“There is no limit,” he says. “The question is, where’s the market?”

Lapsa says it would be “amazing” to realize Musk’s long-range vision of building a city on Mars, or Bezos’ vision of having millions of people living and working in space.

“But I think for those things to come true, there needs to be a diverse, healthy, profitable economy with multiple sectors and verticals in space. There needs to be lots of competition in space,” he says. “Those are the ingredients I think it will take to actually see those things come to fruition. So we’re focused on that, and then wherever the market takes us, that’s what we’ll pursue.”