Federal regulators responsible for the safety of the U.S. drug supply are facing challenges in resuming inspections of pharmaceutical manufacturing firms that have been overdue for surveillance inspections since before the COVID-19 pandemic. An analysis of FDA data by The Associated Press found that roughly 2,000 plants, representing 42% of registered facilities, have not been inspected since before May 2019. This raises concerns about potential contamination and other issues in drugs used by millions of Americans, including critical medications like antibiotics, blood thinners, and cancer therapies.

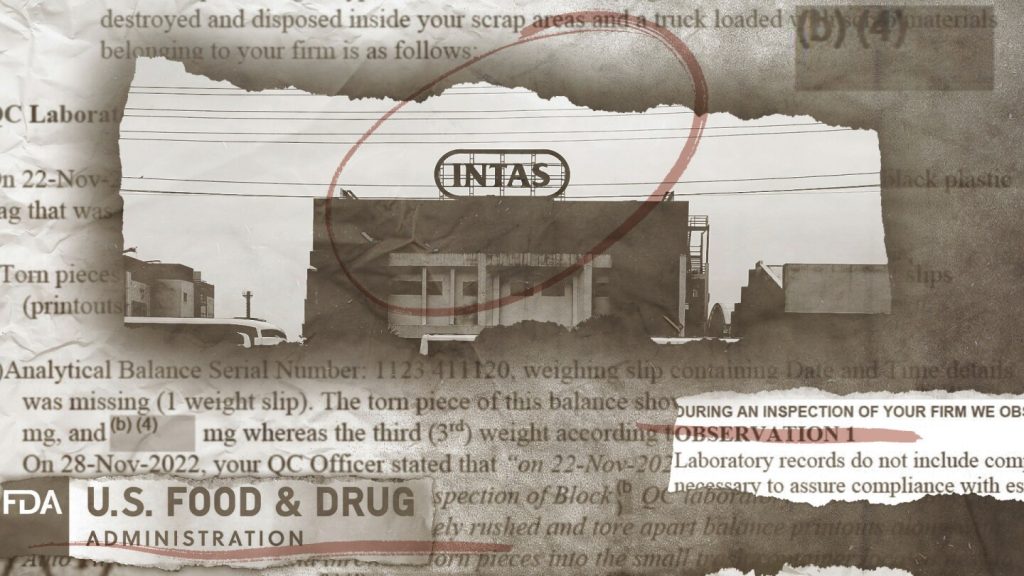

The FDA’s own guidelines state that factories that have not been inspected in five or more years are considered a significant risk and should be prioritized for mandatory inspections. While most of the overdue plants are in the U.S., more than 340 are located in India and China, major sources of drug ingredients for low-cost U.S. prescriptions. The halt in inspections of overseas plants due to the coronavirus outbreak in 2020 contributed to the current backlog, with FDA struggling to address the issue and facing challenges when conducting inspections in countries like India.

The pressure on generic drugmakers to cut costs could lead to compromises in quality if inspections are not conducted regularly. Tragic incidents, such as tainted eyedrops from an Indian factory causing an outbreak of antibiotic-resistant bacteria, highlight the importance of monitoring drug manufacturing facilities for safety and quality. The FDA has increased drug inspections each year since 2021 but still faces a backlog of uninspected plants, with last year’s inspection numbers down almost 40% from pre-pandemic levels.

The FDA’s ongoing struggles in overseeing the global pharmaceutical supply have been documented by the Government Accountability Office, which has identified the area as a high-risk issue since 2009. With drug manufacturers increasingly shifting production overseas in search of cost savings, the FDA has been playing catch-up in conducting inspections and ensuring the safety of drugs entering the U.S. market. The agency’s efforts have been hampered by a wave of staff departures, budget limitations, and challenges in retaining experienced inspectors.

The FDA’s approach to monitoring drug manufacturing facilities is under scrutiny, with lawmakers raising concerns about the agency’s ability to address its inspection backlog and ensure the quality of medications. House Republicans have questioned the decrease in violations reported by FDA inspectors in Asia, suggesting that fear of triggering additional drug shortages may be a factor. A pilot program initiated by the U.S. Defense Department in collaboration with a private laboratory aims to monitor drug quality through laboratory testing, highlighting potential alternatives to traditional inspection methods.

As the FDA grapples with staffing shortages and challenges in conducting inspections, experts suggest exploring innovative solutions, such as incentivizing pharmacy chains and drug distributors to prioritize purchasing from high-quality manufacturers. The global nature of drug manufacturing poses complex challenges for regulatory agencies, and there is a growing recognition of the need for a more comprehensive approach to ensuring drug safety. The ongoing efforts to address the FDA’s inspection backlog and enhance oversight of drug manufacturing facilities will be critical in safeguarding the U.S. drug supply and protecting public health.